Construction & Engineering Awards 2024

Журнал BUILD объявляет победителей конкурса Construction and Engineering Awards 2024 От противопожарной защиты до продуктов UHPC, сантехники…

Журнал BUILD объявляет победителей конкурса Construction and Engineering Awards 2024 От противопожарной защиты до продуктов UHPC, сантехники…

NEWSLETTER May 2020 Thank you to all of our F.A.S.T. assemblers out there for what you do,…

Accelerator – the regulator of the amount of combustible mixture entering the cylinders of an internal combustion engine. It designed to change the engine speed (the speed of the machine).

Accelerator control system necessarily has a gas pedal / shifter / joystick / control knob, by pressing on which increases the amount of air-fuel mixture supplied to the combustion chamber of internal combustion engines.

Currently, there are many accelerator control options, but the most common – is the conventional mechanical pedal with rods or cables, as well as electronic pedal. The special equipment is widely used manual control modules driven by levers, shifters, etc.

The following is a description of these devices offered now “Systems of Control – ConSys“.

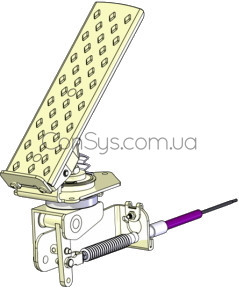

Mechanical pedal designed by the renowned firm Felsted and is widely used for heavy-duty trucks, buses, agricultural machinery, construction equipment, and virtually all other mechanisms, which can be controlled with the foot drive. For versatility pedal is rotatable by 360 ° around the axis.

Fig.1. Shifter for continuous / discrete control

Offered shifters (Figure 1) have the ability to work as a discrete (moving the control cable on a step) and continuously (by moving the control cable to any amount up to the maximum cable travel). Shifters design can be for light loads (with cables series 4) and heavy loads (with a series of cables 6).

For convenience shifters are equipped with LED indication of cable position.

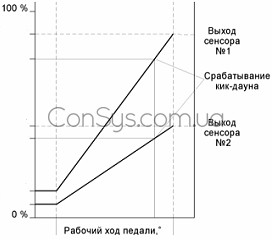

Fig.2. Electronic floor mounted pedal with built-in kick-down

By design pedals can be floor mounted (Fig.2.) or suspended (Fig .3).

The main part of pedal is the sensor of pedal position (in this pedal – contactless sensor using Hall effect), which continuously determines its location and sends the relevant information in an analog form of the engine control unit.

Fig.3. Suspended electronic pedal

To improve reliability, the module uses two identical sensor (one of them is loaded with additional resistance), thereby forming two different signal characteristics. Control unit are analyzed sensors signals and compared with the set and on the limit values of voltage modes are identified “kick-down” and idling.

Fig.4. Hand throttles control

Each position sensor has its own separate wires for Voltage Supply, Ground and Signal.

Throttle control housing – a kind of gearbox, which offers the possibility of very smoothly adjust the supply of fuel by varying the gear ratio.

Such a construction of throttle control often used when need for duplication of the accelerator control, for example in the case of rotary vehicle cab (excavator, a crane, etc.).

More detailed information about pedals and shifters please see on our site:

Systems of Control – ConSys