Construction & Engineering Awards 2024

Журнал BUILD объявляет победителей конкурса Construction and Engineering Awards 2024 От противопожарной защиты до продуктов UHPC, сантехники…

Журнал BUILD объявляет победителей конкурса Construction and Engineering Awards 2024 От противопожарной защиты до продуктов UHPC, сантехники…

NEWSLETTER May 2020 Thank you to all of our F.A.S.T. assemblers out there for what you do,…

In conventional engine control systems, the engine is operated by acting on the accelerator pedal, which is mechanically connected to the high-pressure fuel pump (High Pressure Fuel Pump – Diesel Engine). The force from the accelerator pedal to the high-pressure fuel pump is usually transmitted through the remote control cable, sometimes, in earlier designs, using mechanical rods. In modern engine management systems, remote control cables, and especially mechanical traction, are absent. The efforts of the driver when you press the pedal are recorded by the pedal position sensors and in the form of electrical signals, depending on its angular position, are transmitted to the electronic control unit (ECU). The proposed pedals use a non-contact sensor using the Hall effect, the characteristics obtained from which are a function of its angular position of the pedal. For protective or diagnostic purposes, in case of a malfunction of the main sensor, an additional sensor can be installed. Incoming and outgoing voltage characteristics are set during the manufacture of pedals and are presented in the form of graphs for calculating the stroke or angular movement of the pedal.

For vehicles with automatic transmission, a kick-down sensor can be installed also.

Coordination of the use of ConSyS electronic pedals:

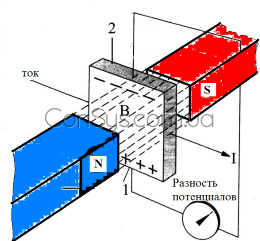

The principle of operation of the proximity sensor:

NON-CONTACT SENSOR:

Hall Effect = No Contacting parts

Not affected by lateral force

Not affected by environment

Programmable output signals

SENSOR life : >80,000,000

Switch position +/-1%

Floor pedals:

30 ° angle small foot print or 38 ° angle

Outboard pedals:

Polymer Sensor Integrated Direct Drive or Polymer Direct Drive

· Eliminate signal loss and provide a stable signal for EMC

· Meet EMC requirements + 800 discrete(10bits) high resolution signal

· Long endurance life ( > 10,000,000 full stroke cycle)

· Stable against environmental changes, vibration, temperature, moisture, lateral force

Characteristics of the dependence of the supply voltage on the pedal stroke:

a) floor pedal:

b) suspension pedal: